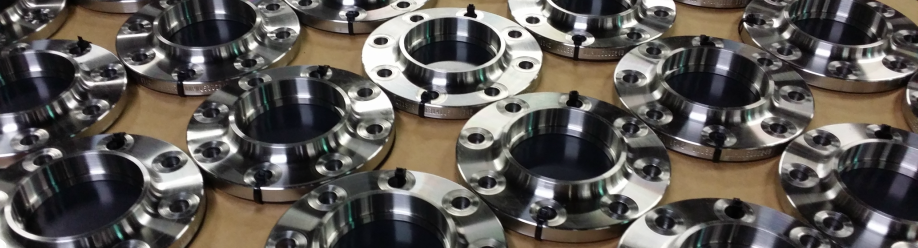

Piping Supplies has seen many changes in the industrial pipe, valve and fitting industry during our 60 years in business. One of the more current trends is the use of Monel 400 flanges for saltwater applications. Piping systems which have traditionally used stainless steel are being converted to Monel 400. Here is why.

Monel 400 is a copper and nickel alloy invented in the early 1900’s. It has been found to have excellent corrosion resistance and can withstand exposure to acids well. Monel 400 does well under pressure and is relatively easy to weld. All of these properties make it a great choice for underwater drilling and for the Navy.

The alloy, Monel 400, is composed of 28 to 34% copper and at least 63% nickel with traces of manganese, silicon, iron, sulfur and carbon. Nickel makes this alloy strong and resistant to corrosion while the copper allows for conductivity and ductility. Our machinists find the machinability of Monel 400 to be only slightly tougher than stainless steel grades.

The Navy has been converting some of their piping systems to Monel 400 in recent years. The volatility of the worldwide nickel market has made this metal harder to obtain. That has driven costs higher increasing the overall price of shipbuilding. Hopefully the the increase in lifetime of these piping systems will offset the higher costs.

Monel 400 is the most recent favored metal for flanges in saltwater applications. The only thing for sure is that newer more exotic materials will be developed in the future. The expert machinists at Piping Supplies will be ready for whatever happens.