A uniform set of rules can even out results across the board. Meeting these goals can provide consumers with additional confidence while streamlining processes for workers. On the other hand, it takes time and resources to achieve International Organization for Standardization (ISO) 9001 certification. The standardization benefits can translate to a time-consuming and costly process. Piping Supplies Inc., a flange manufacturer and pipe making supplies provider, is conscious of both sides of this issue.

In short, ISO 9001 family of regulations is the “international standard for a quality management system” and certification does not depend on company size, industry products. According to The Standards Stores, a provider of management system toolkits, the roll-out of an effective Quality Management System that adheres to ISO 9001 standards will ensure “appropriate and effective” operations. It’s important not to over-complicate things and this example of how ISO 9001 can be applied to baking cookies shows us the significance of internal and external issues, parties involved, scope and quality management.

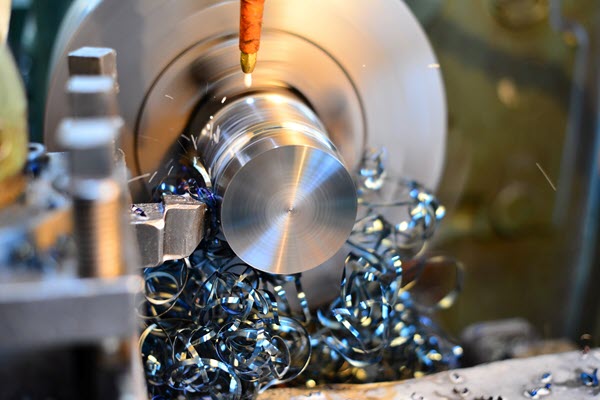

Manufacturing is a process rooted in exact measurements and tasks carried out hundreds of times to render identical results. When creating pipe flanges, our machinists are expected to take custom dimensions and machine a unique part. Now that we’ve explained the basics of ISO 9001, it’s easy to see how the expectations are applicable. A flange manufacturer who is producing pipe flanges for customers will need to consider some of the following when taking on the order: efficiency and productivity, waste reduction, consistent results and how these plans could be provided to smaller and larger firms. Customers expect pipe flanges to perform as intended once installed; our efforts to properly thread and bore every flange exactly the same is what ISO 9001 is all about.

To play devil’s advocate here, does a flange manufacturer really need to be ISO 9001-certified? Our pipe making supplies have been tried and tested and our reputation for one-off orders and meeting exacting demands speaks for itself. It takes time to learn, implement and adhere to these standardizations – and that’s time taken away from the actual manufacturing work that we do. If the pipe flanges we’re currently producing are pleasing customers every single time, should our small machine shop be concerned with such subjective goals? Even if ISO 9001 is a globally-accepted form of standardization, Piping Supplies Inc. is often more concerned with our local customers around the corner. In fact, it’s these clients that have helped us solidify such a positive reputation over our 50 years of operation. These are all important decision we must make internally and since it can affect the outcome of our projects, it’s one we take very seriously.