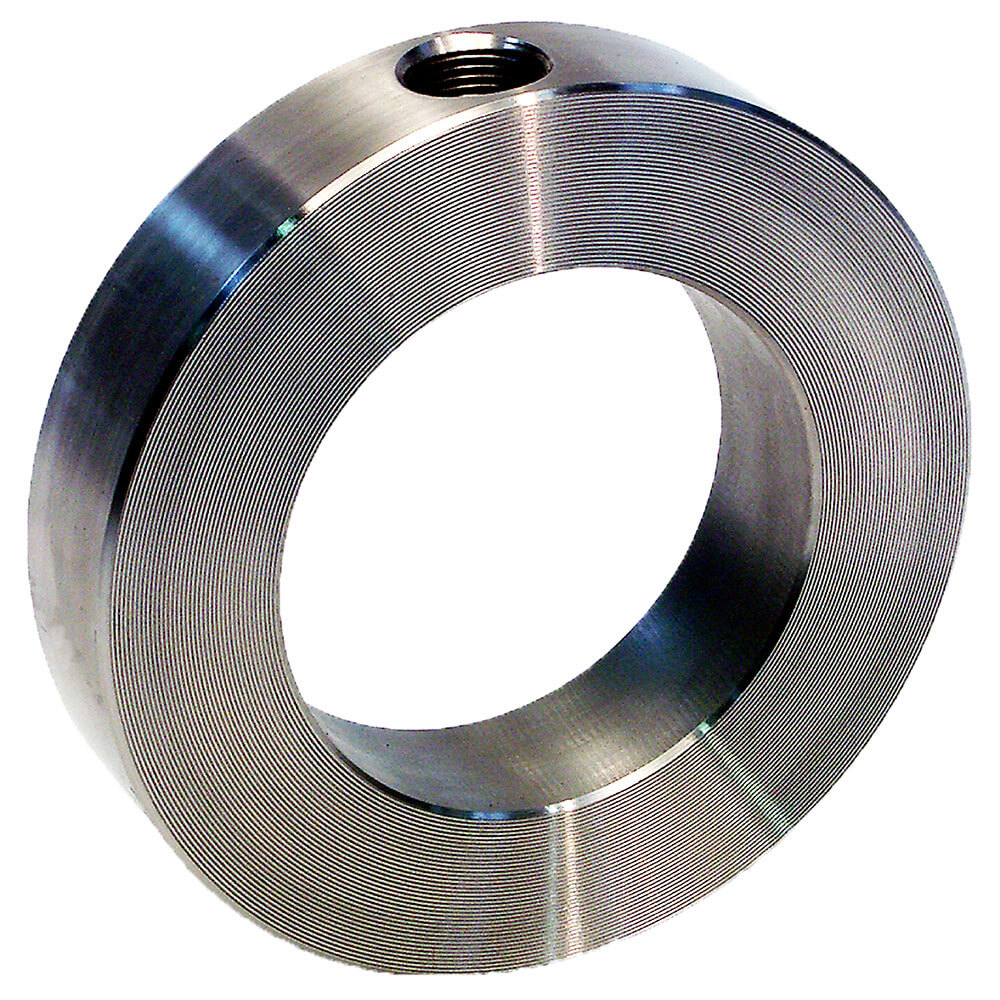

In industrial piping systems, bleed rings can be an economical and better solution to orifice flange sets. What is a bleed ring you ask? You may have heard it called a drip rings, vent rings, bleeder rings, or test inserts. Whatever you call it, it is simply a metal ring, usually 1-1/2″ thick, with a 1/2″ NPT or 3/4″ NPT threaded outlet on the outside diameter with a hole going to the center of the ring.

Bleed rings are sandwiched between two flanges with gaskets. The threaded outlet can be attached to testing equipment to monitor what is happening in the pipeline. It can also be used as a drain outlet. Bleed rings can be used to release pressure in a piping system before repairs or replacements are made.

Bleed rings can be made in many materials including carbon steel, stainless steel, copper-nickel, Monel Inconel or any other steel used in piping systems. Because bleed rings are smaller than an orifice flange set, it can be far less expensive especially where exotic materials are required.

Our flange manufacturing experts can make custom bleed rings with multiple outlets which may require a thicker part. We can also make bleed rings with socket welding outlets instead of pipe thread outlets. The versatility of bleed rings along with their cost savings over orifice flanges may be a great solution for your piping system. Besides that, orifice flanges are more difficult and time consuming to make so our machinists like making bleed rings more. And, happy machinists make better parts.