Steel prices have been rising steadily from 2019 through 2021. Everyone in the steel manufacturing, steel fabrication, shipbuilding and pipe, valve and fitting distribution industries know this. As a manufacturer of steel and alloy pipe flanges for over 50 years, Piping Supplies has seen their share of these raw material price increases. Some price increases can be absorbed but at some point, costs must be passed to our customers.

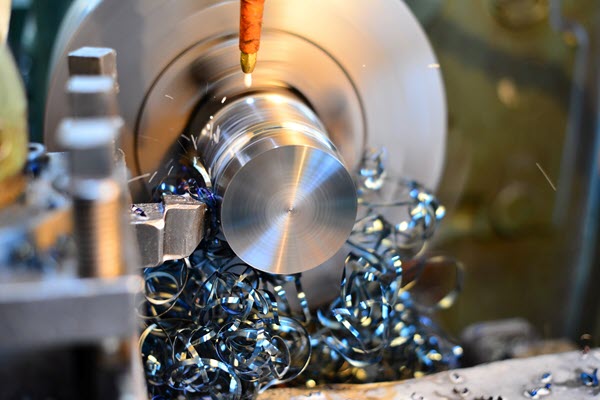

To keep our prices low and our customers happy Piping Supplies constantly evaluates and improves our production processes. We invest in new machinery every year to take advantage of the latest manufacturing efficiencies. New equipment will only take you so far. The most effective way to keep costs low is by being able to produce the first piece in a production run as fast as possible. The time to produce our first piece in a production run is now an average of 1 hour down from 3 hours a year ago. This was achieved by better organization, streamlining of the programming process on our CNC machines, tooling standardization and better item run-time documentation. Because of this, we can make smaller quantities cheaper and faster while reducing the overall costs of longer production runs.

Even expert flange manufacturers like us would not have been able to see dramatic results like these without a collaborative effort. Every department participated including accounting, sales, purchasing and, of course, shop production. We at Piping Supplies are proud of the flanges we make for the Navy, oil refineries, power generation, chemical plants, and tank fabricators around the country. Making great precise flanges would not be possible without a great team who always have the customers best interest in mind to make it all happen.